As there is increasing interest in two-stroke engines, it may be apposite to describe a design which I hope to make when conditions permit. It is similar to Mr. Reid’s engine (described in The Motor Cycle for 29 November, 1951), but it is simpler and incorporates a feature which may bring the ‘split-single’ type of two-stroke into a leading position. This feature is a reduction in size of the inlet cylinder relative to the exhaust cylinder, so that less of the burnt charge has to be reversed at the end of each power stroke.

The advantages of the split-single engine are partly offset by its limited speed. I think that the cause of this is obvious, namely, that part of the burnt charge which has driven the piston down the inlet cylinder has to he reversed via the cylinder head before it can reach the exhaust ports; and high engine revs are not attained before the stage is reached where these reversed gases arrive too late at the exhaust ports.

Improved performance

All split-single engines of which I have heard have equal working capacities of inlet and exhaust cylinders; therefore, half of the burnt charge has to be reversed as described. I contend that improved performance can be obtained if the inlet-side capacity is reduced and outlet-side capacity increased. The limit to this improvement is reached just before the inlet cylinder becomes too small to accommodate inlet ports of sufficient area.

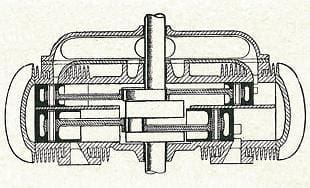

An engine with this improvem ent, and suitable for motor cycles, is shown in the drawing. It is a horizontally opposed type, with four cylinders and two cylinder heads. The larger (exhaust) pistons are linked to the crankshaft in the usual manner. The smaller (inlet) pistons, having a shorter stroke farther from the crankcase, can work through rods on an eccentric, thus allowing the use of a stiffer and more compact engine-shaft than would be the case if two crank throws were required. The exhaust pistons run slightly ahead of the inlet pistons, of course, although this is not shown in the drawing.

ent, and suitable for motor cycles, is shown in the drawing. It is a horizontally opposed type, with four cylinders and two cylinder heads. The larger (exhaust) pistons are linked to the crankshaft in the usual manner. The smaller (inlet) pistons, having a shorter stroke farther from the crankcase, can work through rods on an eccentric, thus allowing the use of a stiffer and more compact engine-shaft than would be the case if two crank throws were required. The exhaust pistons run slightly ahead of the inlet pistons, of course, although this is not shown in the drawing.

Due to the shorter stroke of the inlet pistons, the inlet ports are farther from the engine-shaft, and this permits the use of a centrifugal blower large enough to give the needed boost without gearing up. This type of blower mounted direct on the engine-shaft must be the cheapest and most trouble-free ‘blowing’ method possible. The inlet manifold consists of the annular passage shown at the blower centre, and a vertical pipe to that passage from the carburettor.

I submit that this engine offers more for less than almost any other type. The port timing can be varied, at the design stage, to give anything from extreme economy to high power output, with a good power-to-consumption ratio in any case. It is simple and has few small parts, making for reliability, retention of tune and reasonable cost. The even firing at low speeds is here, as with normal split singles, yet without the usual limited speed of this type. The power impulse frequency is that of a four-cylinder four-stroke. The engine is compact and accessible, and can either be air-cooled or, in Iiquid-cooled form, made with a smooth exterior.

German luxury lightweight

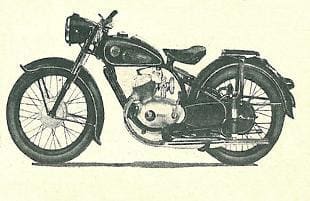

A new 198 c.c. Durkopp, known as the MD 200, is announced from Germany. The new model abounds in novel features which, in this country, would place it in the luxury class. Its price in Germany is not disclosed.

Among the new machine’s features are a hydraulically controlled, telescopic front fork, plunger-type rear springing, a totally enclosed rear chain and centrally disposed, light-alloy brake drums approximately 6in (150mm) in diameter. Mudguards are Continental styled: that is to say they are well rounded and of sensibly deep section. The headlamp incorporates a lighting switch and contains the speedometer within its pressing. Tyres are 3.00 x 19in front and rear; the front tyre is ribbed and the rear has a normal studded tread.

Powering the MD 200 is a two-stroke engine with a light-alloy cylinder and head, and a flat-top piston. The piston is very long and has the gudgeon pin situated roughly mid-way along its length. It has three compression rings and is cut away on the skirt to give increased transfer ‘dwell’.

Features of the light-alloy cylinder are its extraordinarily deep finning and its steeply tapering, twin exhaust ports. From a small diameter at the bore, the ports are full exhaust-pipe diameter at the fin tips. Scavenging is claimed to be extraordinarily good. The silencers are situated unusually far forward and fitted with very long tail pipes. Each tail pipe is drilled, sleeved diametrically and fixed to the bottom of the rear plunger unit by means of a vertical bolt passing through the sleeve.

Features of the light-alloy cylinder are its extraordinarily deep finning and its steeply tapering, twin exhaust ports. From a small diameter at the bore, the ports are full exhaust-pipe diameter at the fin tips. Scavenging is claimed to be extraordinarily good. The silencers are situated unusually far forward and fitted with very long tail pipes. Each tail pipe is drilled, sleeved diametrically and fixed to the bottom of the rear plunger unit by means of a vertical bolt passing through the sleeve.

Bore and stroke of the engine are 61 x 64mm respectively. Power output is claimed to be 10.2 b.h.p. at 5,500 r.p.m. The three-speed gear box, giving internal ratios of 2.63, 1.38 and 1 to 1, is in unit with the engine. The top gear overall ratio is 7.24 to 1. Ignition is by Norris flywheel magneto which incorporates direct-current lighting coils.

The battery and electric horn are neatly housed in a metal container fitted on the right of the machine between the seat and chain stays. The tool box is situated in the tank top. Fuel capacity is 12 litres. Height of the cantilever-type saddle when the machine is unladen is 740mm, (approxiniately 29in). The finish is black and chromium, with white lining on the tank, wheel rims, battery container and rear chain case. View original article

See also Record-breaking at Bonneville